Online Jewelry Training Classes for Metalsmiths

One of my big bugbears in jewelry making was wire ingots.

As if heating this big bar of pig iron up to temperature and then using a cigarette butt as stopper wasn't bad enough, trying to get the ingot out was often problematic.

Especially with white gold, which often has a tendency to 'solder' onto the iron.

I have been using the method described below for about 15 years ans I personally think its a vast improvement over the commercially available casting ingots.

I make it out of normal mild steel that is available at hardware stores.

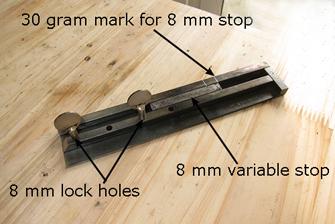

The base is 200 mm long and 40 mm wide and 4 mm thick.

The rest is 8 mm square bar.

And 100 mm length of 5 mm rod that the lock pins are made of.

Then I tap all the holes in the square bar with a 4 mm tap.

Casting anything smaller than 5 mm square is not efficient because it becomes to finicky to pour and you spend more time fixing a bad cast than working.

Because I cast a known weight into a fixed cavity, it means that I always get a perfectly cast metal bar.

I have another ingot mold in this fashion that goes up to 10 mm square, but I so seldom use the large size. So, I only designed this ingot to be used for most of the general use in general metalsmithing.

Namely, 5 mm and 8 mm in the 20 to 30 gram range is basically what gets used the most in general small workshops.

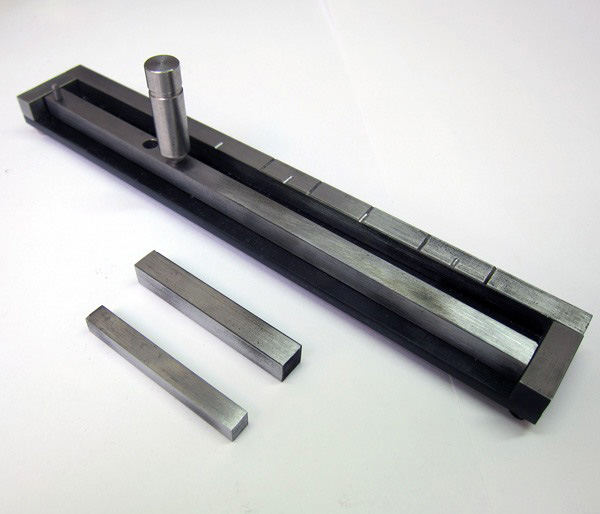

The bottom of the metal ingot bars as they come out.

More information here on this Adjustable Wire Ingot Mold which is for sale. Or place your order below.

The fully adjustable and easily removable cast bar is a main feature of this wire ingot mold.

This makes for a perfect cast each and every time.

It's easy to use and designed to cast small amounts of metal.

The ingot mold heats up and cools down quickly.

Ships within 5 days

For buyers witin EU 21% VAT will be added

Price : US$ 112

Worldwide Standard Parcel Post Rate of US$18 is added at checkout.

Video showing how metal scraps are cast into a bar using the adjustable ingot mold.

or select other projects from Jewelry Making Tutorials List

If you have any questions or wish to be notified of any new tutorials that are posted, email me.

This content is the intellectual property of Hans Meevis. More information on our Copyright and Privacy Policy