Online Jewelry Training Classes for Metalsmiths

I got some experience in casting insects. It was a hobby of mine. My workshop used to be in a hotel and the management was very liberal with poison, much against my will. This resulted in many insects being killed, thus many castings. I only used spin casting and I only was successful about 80% of the time. Also, only cast insects in absolutely perfect condition.

When your Orb spider has finished her egg sac, you might as well catch her and kill her. Reason ? As she dies she will crawl off somewhere and you won't find her, or she'll drop to the ground and the ants will damage her. Besides, they start shriveling up soon after they done the egg thing. The best way to kill any insect is to put it in a bottle and freeze it. This also allows you to choose the time of casting.

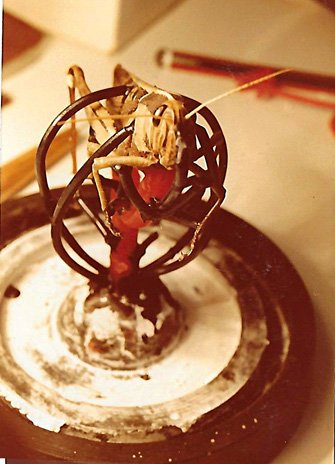

I sprued up as follows: On the thorax of the insect, at the bottom, I put the main sprue, about 6-10mm thick. I make it as thick as possible, even as thick as the width of the abdomen.

A side view of the locust legs sprued.

An Orb spider has very thin legs. This is a problem. You have to sprue each leg just above the foot, sometimes on the shin and also on the thigh ( sorry, for using non-scientific terminology). With an Orb I would probably use 4 sprues on each leg 1.2mm thick, only on the smooth parts.

Also you have to thicken all the joints with a bit of wax applied with a hot needle. If you don't, there will be porosity there, and they will break off after casting. Normally sprues will be about 1-2mm thick. From the main sprue a 2.5mm sprue will go to under the pedipalps. Always sprue underneath the insect. Thicken the joint with wax between the head, thorax and abdomen if necessary.

A 3mm sprue will go to under the middle of the abdomen from the main sprue. Your Orb will have 35 sprues when you finished. A spider abdomen becomes soft after thawing and deforms under its own weight as it rests on the sprue.I think an Orb won't ( I have never cast one) but I think they have a harder skin than the soft furry abdomen of say a Sun spider. Low temperature wax applied with a very hot needle permeates into the skin without loosing too much detail and solves the problem somewhat. I have learnt that over sprueing is always the best. It makes finishing of a real mission but it is better than having a miscast.

I always cast in silver and I make up a fresh alloy at 95% fine silver with 5% deox alloy. I don't use copper although I have been successful with a 97% solution. Fine silver does not work for me. I use higher purity alloys because when the insect is sprued up it is not in a natural position and therefore it makes bending it back easier after casting.

I use Satin Cast 20. First I mix up some plaster and paint it on the insect. Then as it starts to gloss over I mix more and paint on more. I do this at least three times. If you let it harden too much between the layers they separate and you get major flashing.

As the last layer glosses over I put the flask over and pour it full. Obviously vacuuming is not an option. I would use a 4 inch flask for that size spider and I would carve the button cavity about a third larger, so you can put a LOT of metal in. No less than 100- 150 grams.

I burn out for 8 hours at least. Centipedes, as they burn out, for a long time smell like baking biscuits (no kidding) Most insects smell like Satan's own cesspool.. Be warned… I use a normal cycle, then I keep the temperature at 700 to 750 Celsius for at least two hours sometimes more. I cast at 650-700 Celsius. I don't get sulphur contamination. I wind my spin casting machine two and a half times normally, but for insects I add one more turn. As soon as the button is not red in neon light I quench. I had never had temperature tear yet…

I use Satin Cast 20. First I mix up some plaster and paint it on the insect. Then as it starts to gloss over I mix more and paint on more. I do this at least three times. If you let it harden too much between the layers they separate and you get major flashing. As the last layer glosses over I put the flask over and pour it full. Obviously vacuuming is not an option. I would use a 4 inch flask for that size spider and I would carve the button cavity about a third larger, so you can put a LOT of metal in. No less than 100- 150 grams.

I have often wondered if electro polishing would not be a better option, on account of all the fine little hairs get broken off with a steel brush., Maybe someone could tell...Here I cast a centipede and the silver cuff together.

I have never been successful with winged insects, even if I thicken up the wings with wax.

Here the feet of the scorpion cast are incomplete.

I have successfully cast the legs and claws of a road kill Pels Fishing Owl. I know the bone did not burn out completely, being calcium, so I assume that the silver encased it. I have never been successful at casting sea shell or coral. I vulcanize it and cast instead.

Please note that all insects shown were either dead or dying.

or select other projects from Jewelry Making Tutorials List

If you have any questions or wish to be notified of any new tutorials that are posted, email me.

This content is the intellectual property of Hans Meevis. More information on our Copyright and Privacy Policy